The use of non-contact shaft seals is not new, but recent advancements in contactless shaft seal technology have significantly expanded their capabilities. The seals used for most bearing assemblies often go unnoticed, until failure leads to costly downtime or operational interruptions. As life cycle costs become more important considerations, engineers are placing more emphasis on optimizing the design of bearing seal designs as part of comprehensive industrial sealing solutions.

Modern innovations mean engineers no longer have to accept the traditional limitations typically associated with the standard labyrinth seal. Instead, evolving technologies have led to the development of hybrid labyrinth seals and advanced centrifugal shaft seals, expanding the performance and reliability of rotating equipment seals. Today's non-contact shaft seals offer longer service life, reduced wear, reduced heat generation, and no parasitic drag. Our manufacturing experts can help you to select and custom-design an ideal non-contact seal for your unique application.

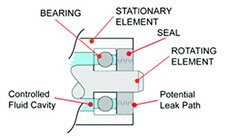

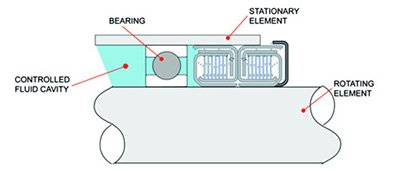

Seals play a critical role in protecting rotating systems by keeping lubrication in and contaminants out of a controlled seal cavity. Non-contact seals are designed specifically for applications where fluids must remain contained between two elements, without physical contact that can cause wear or energy loss.

A typical sealing application includes a stationary component, a non-stationary (or rotating) element, and a controlled fluid cavity between them (See Fig. 1). Traditionally, basic lip seals have been applied in this type of environment. However, their limitations, especially in high-speed or high-temperature environments, prompted the development of more advanced industrial sealing solutions.

Non-contact shaft seals emerged as a high-performance alternative for applications involving extreme shaft speed or where the durability of a traditional lip seal was limited. Unlike lip seals, which maintain direct contact between a flexible sealing lip and the rotating surface, contactless shaft seal technology eliminates that friction. In lip seals, this constant contact creates wear on both surfaces and generates significant parasitic drag to the system. As speed increases, the lip can overheat, deform, or even lift away from the shaft due to centrifugal forces, ultimately causing seal failure. By contrast, centrifugal shaft seals and other non-contact options reduce wear, minimize drag, and improve reliability in rotating equipment seals.

Non-contact shaft seals are designed to seal without any physical contact between the rotating and stationary elements. In general, the benefits of non-contact seals include:

The type of non-contact seal chosen for an application determines its specific benefits. The key to successfully employing any non-contact seal is to understand the sealing methods, and to select the appropriate seal configuration for each specific application.

Non-contact shaft seals available in today's marketplace can be classified by their design characteristics, and include:

Each type of seal has specific advantages and limitations. To determine the applicability of each seal, the engineer must examine the performance of the seal during each of three normal operating modes:

Labyrinth seals offer a non-contact method to prevent leakage through a complex path, suitable for high-speed applications but may allow some weepage when stationary. There are several types of labyrinth seals. Typical labyrinth seals incorporate a "maze" or a set of rings in extremely close proximity, to capture the lubrication and push it back toward the controlled fluid cavity. Rings in close proximity form a barrier by shearing the fluid, centrifugally slinging the lubricants from the rotating seal element to the stationary seal element in a series of steps (See Figure 2).

The labyrinth seal is constrained in its ability to function with a wide variety of fluids due to its limited ability to centrifugally push the lubricants back into the controlled fluid cavity. In addition, it can only handle a limited volume of lubricating fluid in the controlled fluid cavity, and it requires high rotational speeds to seal adequately. The seal is not able to keep out external environmental contaminants entering the controlled fluid cavity when the seal is not rotating, and some fluid "weepage" is expected from the seal. In general, the standard labyrinth type seals have limited abilities when reviewed in terms of the three operational modes:

Hybrid labyrinth seals incorporate contact elements that disengage at operational speeds, balancing sealing effectiveness with reduced wear. The hybrid labyrinth seal has been modified by adding a contact seal component designed to centrifugally lift off the rotating shaft when the seal is operating at normal speeds. This modification solves some of the limitations of the standard labyrinth seal, and makes it function more like a contact lip seal. In addition, a lip seal component can be incorporated such that it will only make contact at lower speeds and will centrifugally lift from the contact surface at higher speeds. While the hybrid labyrinth seal does solve the problem of contaminants entering the controlled fluid cavity when the seal is not rotating, it adds challenges in mounting the seal and controlling axial movement, and reduces the efficiency of the seal by adding a contact element.

In general, the hybrid labyrinth type seals have limited capabilities when reviewed in the three operating modes, but in the proper applications they can perform adequately. Hybrid labyrinth type seals offer additional features over the standard labyrinth seal but still have some limitations:

Our experts have detailed tips about centrifugal pressure seals vs labyrinth seals, including specifications regarding speed, operating pressures, temperature range, and more.

Centrifugal pressure seals are non-contact shaft seals that utilize a rotating chamber within the seal to develop internal pressures and pump the sealing fluid back into the controlled fluid cavity, offering superior sealing in both horizontal and vertical shafts with minimal maintenance. (See Figure 3).

The double seal illustrated in Figure 3 will pump the contaminants out of the seal from the nonfluid side of the seal as well as pump the lubricating fluid back into the controlled fluid cavity.

The rotating chamber method significantly reduces the operational speed requirements of the typical non-contact seal and allows the use of extremely low-viscosity fluids, even water. The more fluid that passes from the controlled fluid cavity into the rotating chamber, the greater the pressure inside that chamber to return the fluid to the controlled fluid cavity. The fluid in the controlled fluid cavity will continue to fill the rotating chamber in the seal, until the pressure from the fluid in the rotating chamber is in balance with the pressure in the controlled fluid cavity. At this point the seal will continue to move fluid in and out of the rotating chamber to maintain a pressure balance with the controlled fluid chamber.

The centrifugal pressure seal is still a non-contact seal that solves the alignment issues of other labyrinth seals and actually pumps fluids to create a pressure differential between the environment and the controlled fluid cavity. This pressure differential also prevents contaminants from entering the seal's fluid chamber. These advantages are not available in either the standard contact lip type seal or the labyrinth seals. The advantages are clearer when looking at the three operational modes:

Learn more about centrifugal pressure non-contact seal design from our experts and reach out with questions. Our team is available to answer your questions or provide a quote.

There are currently three types of non-contact shaft seals available in the marketplace: the Labyrinth Seal, the Hybrid Labyrinth Seal and the Centrifugal Pressure Seal. Each offers a different technological solution to a shared engineering challenge. Selecting the right sealing solution requires a clear understanding of each application's demands and the specific performance characteristics of each seal type.

Centritec Seals’ centrifugal shaft seal design offers distinct advantages over traditional options. Unlike standard contact lip seals, Centritec’s non-contact design tolerates greater shaft misalignment, simplifies installation and maintenance, and significantly reduces long-term operating costs. These benefits make it an ideal choice for demanding rotating equipment seal applications where downtime and energy loss must be minimized. The following table highlights some of the operating characteristics among the three seal designs:

| Labyrinth Seals | Hybrid Labyrinth Seals | Centrifugal Pressure Seals | |

| Non-Rotating |

|

|

|

| Shaft Accelerating / Decelerating |

|

|

|

| Normal Speed |

|

|

|

When the proper seal is selected, especially one engineered for performance and reliability, the rewards are significant:

Our non-contact shaft seals are crafted to deliver superior quality and reliability. With a wide range of sizes and configurations, we offer flexible solutions tailored to your specific needs. Our skilled engineers are ready to collaborate with you to develop customized seal designs that optimize your application’s performance.

If you have questions about our non-contact shaft seal manufacturing solutions, please reach out to our team or fill out the form on this page and we will be in contact shortly.

Published: November 29th 2011 • by Michael E. Gamache, President

©The Carlyle Johnson Machine Company, LLC and Centritec Seals, LLC., all rights reserved. Information contained herein is intended for illustrative purposes only. Individual projects and applications vary significantly and valves should be specified for specific applications.

Contact Centritec Seals for more information on our centrifugal seal manufacturer services, or to request a quote for your application.